As an Aircraft Structural Mechanic, I was initially assigned to the Green Side ‘Metal Shop’ located at Larson Gym. This was a large shop that was well equipped with virtually every tool and piece of machinery needed to repair or fabricate any structural metal component needed by the helicopters. The large machinery included an industrial sized metal lathe and a hydraulically operated brake for bending sheets of metal. The back section of the shop had a large paint area fully equipped with ventilation fans conducting the paint overspray and vapors through a large waterfall. We could most likely have re-manufactured an entire helicopter in this metal shop if need be. The need never arose.

Given the nature of the flight operations conducted by the experimental section of HMX-1, most of our work fell into the inspection and preventative maintenance categories. On occasion we would need to change out a windshield in one of the birds or replace a bad cam lock (a quick release cowling or panel fastener). The most significant repair that I can remember needing to be done was when a hydraulic mechanic dropped a screw driver puncturing the sponson on one of the birds. A traditional sheet metal lap joint patch was used to repair the hole which was personally repaired by our shops’ head NCO. He said he wanted to make sure the repair was done right and that he had lots of experience doing them from his time in Viet Nam where it was an everyday event patching bullet holes in the helicopters. Actually, I think he was just bored and looking for something to do after sitting around the shop all day.

It was in this Metal Shop that I learned that metal set and blade tape could be used to fix just about anything that man has ever invented, including helicopters. ‘Metal set’ is a 2-part epoxy ‘glue’ that is silver in color and can join practically any two parts together, while ‘blade tape’ was used for exactly that purpose…to repair or cover small imperfections in the helicopter rotor blades (or anywhere else on the helicopter where we thought we could get away with using it). ‘Blade tape’ is known to the rest of the non-aviation world as ‘duct tape’ and now comes in many colors besides the silver variety that we used. To this day, I still refer to ‘duct tape’ as ‘blade tape’. I also learned that MEK (Methyl Ethyl Ketone) is a wonderfully dangerous solvent that can ‘clean’ just about anything imaginable. I find it interesting that MEK has its own place in the modeling hobbies for gluing (welding!) plastic parts together, among other uses.

The metal shop facilities were made available ‘after-hours’ to all the shop members to pursue their own personal projects. Given the nature of the available equipment, automobile restoration and re-painting were among the most popular after-hours uses of the shop. The restoration of a small, 1960’s, forest green MG sports car was undertaken by our shops’ head NCO, while Sergeant Hershey busied himself repainting his 1948 Chevy sedan. He painted it chocolate brown…of course!

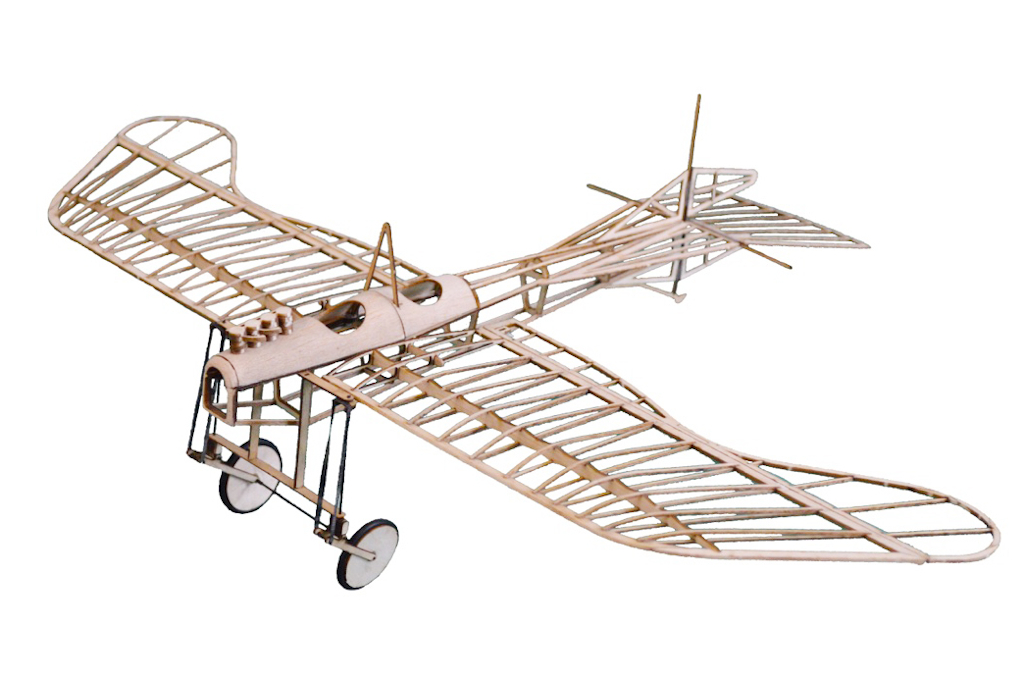

As for me, I busied myself with the construction of a control line model airplane. I don’t remember exactly who made this kit (most likely SIG or Sterling as that is who I was buying all my kits from at that time) but I do remember it was a Mustang profile stunt kit which used a Fox .35 stunt engine. Below is the one surviving picture that I have of me working on the Mustang in the Metal Shop at Larson Gym. It is followed by two photos of the model that were taken in the enlisted barracks where I lived. I stored the model there between my rack and the wall. This model never progressed much beyond what is seen in these photos as it did not survive a barracks inspection. I came back from working at the shop one day to find the model missing. An inspection had taken place during the day and apparently someone felt that this model did not meet USMC regulations. I never saw it again.

(Click on any photo to get a large image with higher resolution)